Add to Cart

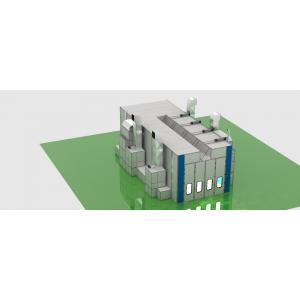

Two sdie wall extraction industrial spray booth opening top folding door

| Technical configuration of Spraying Booth(BZB-FB-1500L) | ||||||||

| Dimension | Inner dimension | 15000×5000×5000 (L×W×H) | ||||||

| External dimension | 16896×5146×5800 (L×W×H) | |||||||

| Room | Structure | Semi drop type, steel composite beam with steel frame structure as framework and steel stiffeners; The wallboard is vertically embedded. The static pressure chamber is on the top of the operating room. Between the static pressure chamber and the operating room, the top net, guide plate and high-quality filter cotton are paved. The height of the static pressure chamber: 800mm; | ||||||

| Wall panel | 70mm thick double sides δ=0.476mm color steel plate, socket type, width: 1150mm, filling material: EPS; | |||||||

| Ceiling panel | Single layer with static chamber in front δ-0.8mm high-quality galvanized steel plate by bending; 50mm thick double-sided without static chamber in the rear section δ= Made of 0.476mm color steel plate, socket type, width: 1150mm, filling material: EPS; | |||||||

| Ventilation | Rear wall exhaust, full drop type, upper supply and lower discharge; | |||||||

| Edging | δ-1.2mm galvanized steel plate and treated by powder spraying; | |||||||

| Main door | Structure | Manual folding aluminum alloy door with 4 leaves, inside and outside δ= 0.476mm color steel plate, 70mm thick, internal filling: EPS wallboard production, equipped with standard gate tempered glass observation window, size: 550 × 1150mm(W × H); | ||||||

| Type | Side entry and exit | |||||||

| Quantity | Door opening size: 4000 × 4650mm(W × H) , 1 group in total; | |||||||

| Service door | Structure | Aluminum alloy frame structure, tempered glass observation window and pressure lock device are adopted to ensure pressure relief in case of excessive indoor positive pressure,Viewing window glass size: 1000 × 400× 5mm | ||||||

| Quantity | Door leaf size: 800 × 2000mm(W × H) , quantity: 2 sets in total | |||||||

| Return air cabinet | Structure | Made of profile and steel plate, inside and outside δ= 0.8mm galvanized steel sheet covering, filled with rock wool insulation material in the middle, and sprayed on the surface; | ||||||

| Quantity | 1 pc in total | |||||||

| Air supply system | Cabinet | The frame is welded with 50 molding materials, inside and outside δ= 0.8mm galvanized steel sheet covering, filled with rock wool insulation material in the middle, and sprayed on the surface; | ||||||

| Fan | YDW series centrifugal fan, model: YDW-5.6M, air volume: 20000m ³/ h. Full pressure: 820pa, power: 7.5kw; | |||||||

| Driving mode | External rotor centrifugal fan | |||||||

| Quantity | 2 × 7.5 kw per group, 1 sets in total, total air supply volume: 40000m ³/ h, | |||||||

| Noise | ≤85dB | |||||||

| Air Exhaust system | Cabinet | The frame is welded with 50 molding materials, inside and outside δ= 0.8mm galvanized steel sheet covering, filled with rock wool insulation material in the middle, and sprayed on the surface; | ||||||

| Fan | 4-82 series centrifugal fan, model: 4-82-6.3E, air volume: 36037m ³/ h. Total pressure: 1076pa, | |||||||

| Motor | Power: 15kw, number of poles: 4 poles, | |||||||

| Driving mode | Pulley drive | |||||||

| Quantity | 15kw for each group, 1 group in total, total exhaust air volume: 36037 m ³/ h, | |||||||

| Noise | ≤85dB | |||||||

| Lighting system | Ceiling light | 18 groups × 4 pieces =72 pieces × 18 W, LED tube; | ||||||

| Installation type | 45 ° on both sides | |||||||

| Bottom light | 20 groups × 2 pieces =40 pieces × 18 W, LED tube; | |||||||

| Installation type | 10 groups of left wall and 10 groups of right wall are installed vertically up and down alternately, | |||||||

| Glass | The lamp is equipped with 4.0mm tempered glass | |||||||

| Lamp box | Standard | |||||||

| Specification | Illumination ≥ 800Lux; Total power: 2016w | |||||||

| Filtration system | Air-inlet filter | G3 primary filtration, filtering out 10μm Dust above | ||||||

| Ceiling filter | F5 filter cotton B to b-560g,can filter out 5μm Dust above | |||||||

| Air-return filter | Glass fiber filter cotton | |||||||

| Exhaust gas treatment | Activated carbon filtration | |||||||

| Duct | Material | Air duct adopts δ= 0.8 the galvanized sheet shall be bent and fabricated, and both ends shall be equipped with die flange connection | ||||||

| Quantity | Straight pipe: 5 sections, 90 ° elbow: 1pc, 45 ° elbow: 1pcs, manual regulating damper: 1pcs, air inlet is equipped with manual regulating damper; | |||||||

| Remark | Air supply pipe with rock wool insulation pipe | |||||||

| Heating system | Heating type | Fuel burning machine + heat exchanger | ||||||

| Heat exchange furnace liner | 1Gr18Ni9Ti stainless steel (SUS304) is used, δ= 1.5mm, made of double-layer heat exchange stainless steel pipe; Enlarged and lengthened furnace liner | |||||||

| Burner | Rl34 Italian riyalu fuel burning machine heating, calorific value of burning machine: 340000 kcal/h; | |||||||

| Change over damper | The pneumatic damper performs internal and external circulation conversion, | |||||||

| Quantity | 1 set in total, maximum calorific value: 5340000 kcal/h; | |||||||

| Chimney | Equipped with 5 straight pipes and 2 elbows, δ= Fabrication of 0.8mm galvanized sheet, | |||||||

| Electric 3D Lift(Optional) | Lifting height | 500-3500㎜ | Lateral expansion | 900-1200㎜ | ||||

| Longitudinal stroke | 13000㎜ | Power | 3KW/set | |||||

| Quantity | 2 pcs / set (1 set for each side), 1 set in total | |||||||

Some of our Project.

----------------------------------------FAQs-----------------------------------------

Are you Trade company or manufacturer?

We are the manufacturer with export liscence.We have two factory in Guangzhou and in Jiangsu,China.

How can we cooperation?

How can we cooperation?

1. Turn Key Project:

Our company will be responsible to help you to do the production line desing,manufacturing,installation,

debugging and your personnel trainging jobs,Also we will provide you one-stop service for your

production facilities procurement.

2. Equipment Supply:

Our company will not only provide you the equipments,but also will offer you the onsite installation

instruction and guidance as well.

How about after sale serivce?

1. Provide technical support and production line upgrade

2. Feedback withini 12h after receive fault notification or service requirement

3. Free training on the user’s manual

4. User-friendly English manual or operation video for machine using and maintanence.

5. One Year Gruantee.